Sista revision: 2010-01-11 /ZIWAMAT

retur

to home index or to the end of this page

![]()

|

ZIWAMAT Ing. KB, Höjdvägen 8, SE-645 97 Stallarholmen/Sweden |

TH2730 (50) is a mechanical test system for

testing new engineering materials and product designs for quality control applications.

We offer an affordable compact mechanic testing

machine for tests on materials and products with smaller forces :

Force up to 3 kN. and now also Force up to 10 kN (new!)

This universal Machine can

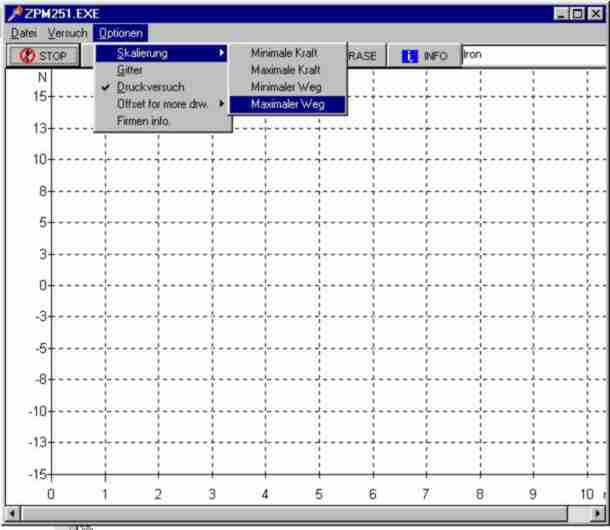

be used standalone or with a Computer (PC). All measuring data

can be transfered using a serial standard interface (RS 232) to a PC.

This machine comes complete with Load

Cell and control

software for Windows.

Test materials and products such as &

-

Biomaterials, tissues, medical devices, components (wire, tubing and needles)

-

Electronic components, connectors, insertion tests

-

Films, adhesive tapes, foils, magnetic tape

-

Plastics, polymers, nylon, acetals

-

Elastomers,rubber,foam,latex, compounds

-

Automotive components, interior structures, foams

-

Packaging materials such as paper, cardboard, wood

-

Cords and Textiles, yarn, strings & threads, fabrics

-

Racquet strings, thin cables, composite fibers

-

Shingles and construction material

drawing for 3KN Model,

click for info!

drawing

for 10KN machin

drawing

for 10KN machin

TH7-5

TH7-5

TH56-K

TH56-K TH229

TH229 TH23-56

TH23-56